Flow sensor FLT-M1

The FLT-M1 flow sensor has been designed to determine the mass flow of liquids and gases. This is done with a mini Coriolis measuring system with an S-shaped measuring tube and a temperature sensor.

The flow sensor is installed directly in a flow pipe via a manufacturer-specific connection. If medium flows through the flow sensor, the measured value information is generated with the aid of Coriolis forces. The measured values are fed to the higher-level system via a Modbus TTL.

It is possible to take flow measurements for pressure lines up to 100 bar at a measuring rate of 200 Hz (200 measured values per second). Flow changes are recorded with a step response time of 50 ms.

Target audience

This product is designed for OEM applications in the field of plant and machine construction, where measuring instruments with high quantities and smallest variance are required. The device has no intrinsic safety, as the flow sensor is designed for integration into a device or system.

•Coriolis-based mass flow sensor for liquids and gases, ideal for OEM applications in plant and machine construction.

•Directly fits into flow pipes and provides real-time data through Modbus TTL communication.

•Features an S-shaped measuring tube and temperature sensor for accurate mass flow measurement.

•Measure flow in pressure lines up to 100 bar with a high measuring rate of 200 Hz and a rapid step response time of 50 ms.

•Measured values include mass flow, density, and temperature, with adjustable units of measurement.

•Max measurement errors of ±0.10% for mass flow and ±5 kg/m³ for density.

•Temperature range from -10°C to +70°C, making it suitable for various applications.

•Hermetically sealed and prepared for electromagnetic compatibility.

•Two variants, FLT-M1_i1 and FLT-M1_i2, with different flow measuring ranges to suit specific needs.

Dosing of delicate or expensive liquids

Measuring:

Dosing of delicate liquids consisting of several components. The flow components have been developed specifically for plant engineers. Highest precision with integrated electronics in combination with a very compact design.

Customer benefit:

- Quality improvement: High-precision monitoring/dosing of the components

- Optimizing the use of resources FLT-Mx Dosierung mit Durchflussmessgeraet

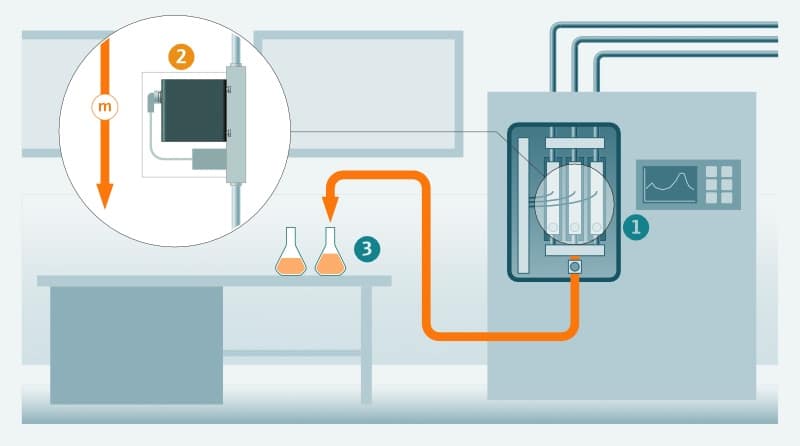

1. System for dosing and mixing of delicate and expensive liquid media.

2. Coriolis for monitoring the mass flow. In combination with a pump or a valve, a control circuit can be set up for optimal dosing.

3. Filling of media into suitable transport containers.